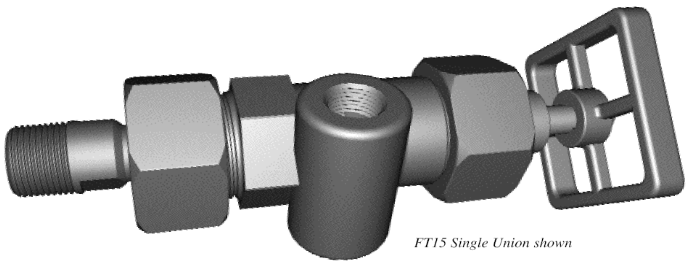

Model FT15/FT25

SIGHT GLASS GAUGE VALVE

“FREE TURN”

valves for

flat glass

gauges

Bulletin FT

Issued 2/11

Replaces 6/10

No Freeze Valves

- Oil & Gas Separators

- Compressor Scrubbers – Especially Suited for Natural Gas Service with Brine, H2S or CO2

- Recommended for Flow-Back Operation after Fracing New Wells with Sand

- Refinery & Gas Plant

4000 PSIG @ 100°F

NACE MR-O1-75 conformance

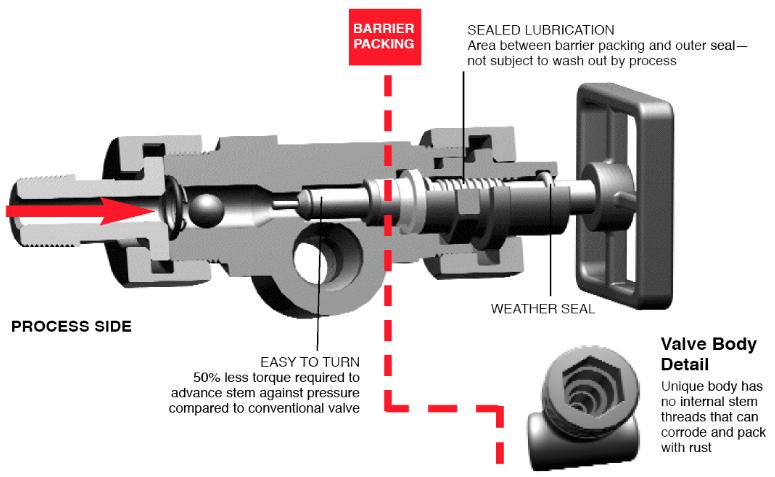

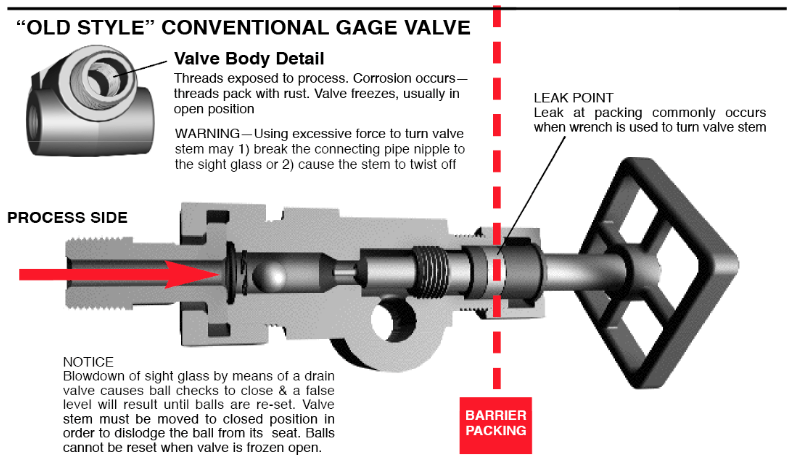

EXCLUSIVE DESIGN…ISOLATE WORKING THREADS

- Sealed Workings– Not vulnerable to process corrosion

- Cost Savings– “FT” valves stay operableâ€no need to add double block valves

- Clean & Readable Sight Glasses – Operable gage valves permit sight glass to be isolated from vessel & accessed for cleaning

- Safer Operationâ€Large wrench not needed to break loose a frozen valve stem operating under high pressure.

- Environmental Advantage – Operator is assured that valve stem is in correct position because the stern stays free to turn. Ball checks are designed to shut off automatically in event of glass breakage but they will not work when valve is partially open. A broken sight glass with no ball check protection can result in environmental spill.

STANDARD BENEFIT

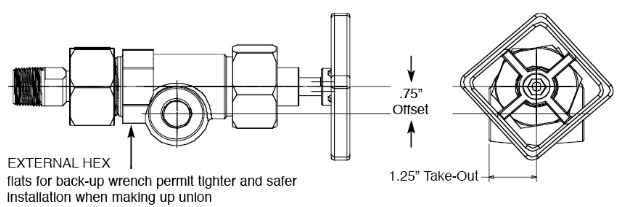

O-Ring Seal

O-Ring improves sealing in union when minor piping misalignment is present. No more paper gaskets!

Replacement Ring size: Parker 2-116

Conventional metal to metal union is designed with one flat face and one beveled face. Tightening the union nut causes the two halves to crush together and seal without the need of a gasket. However when misalignment is present there may be inadequate compression to make a seal.

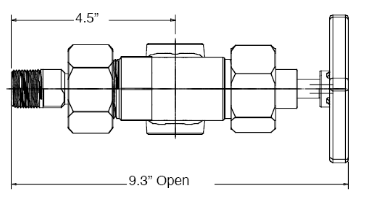

FLOATING SHANK

Vessel Connector “floats” off center by 1/8″ in all directions, more than any other brand. Combined float in upper and lower valves allows for up to : 1/4″ variation in vessel centers.

NAME PLATE INSTRUCTIONS

Safety ball check operation instructions etched on metal name plate and pictured on plastic yellow tag

CORROSION RESISTANT SS TRIM

Stem, ball, packing washer & follower

TFE STEM PACKING

Low friction turning

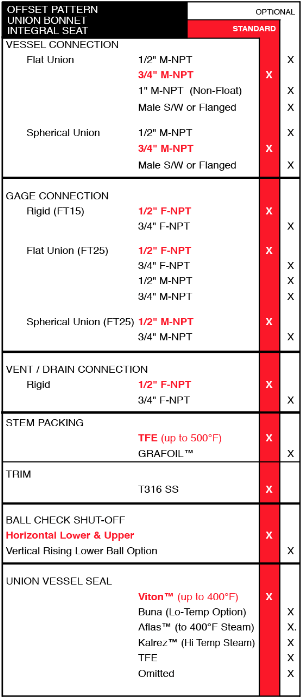

OPTIONAL SPHERICAL UNION

Recommended when angular misalignment of fittings causes excessive strain on piping. Especially useful on compressor packages with VIBRATION.

When the nipple connecting the gage lies in horizontal axis the valve can be rotated on the nipple to provide an additional degree of Freedom.

Adjustment of ball combined With rotation of valve body on the connecting nipple forms a UNIVERSAL JOINT. C-C adjustment is obtained by rotating valve body. Use “Close Hook-Up” style gages with side or back outlets or combine T,s with regular top & bottom connected gages to provide this horizontal connecting axis between gage and valve body.

INFERNO “FREE TURN” DESIGN

PACKING STOPS PROCESS

FROM REACHING THREADED

AREA OF VALVE

Wetted parts conform to NACE MR-01-75

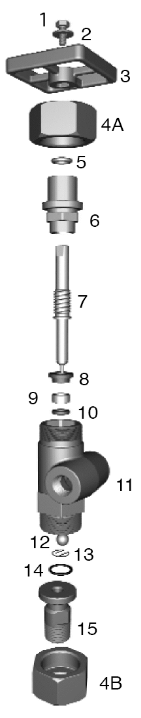

TO TIGHTEN PACKING:

When tightening packing, stem travels with bonnet towards seat. In closed posltlon, seating contact prevents further downward movement of packlng bonnet.

Valve must be at least partially open before packing nut can be tightened.

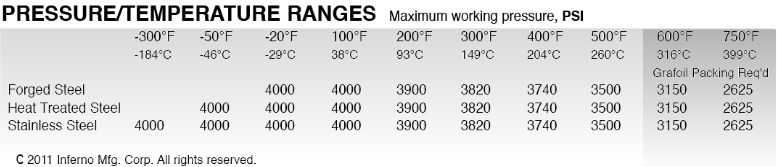

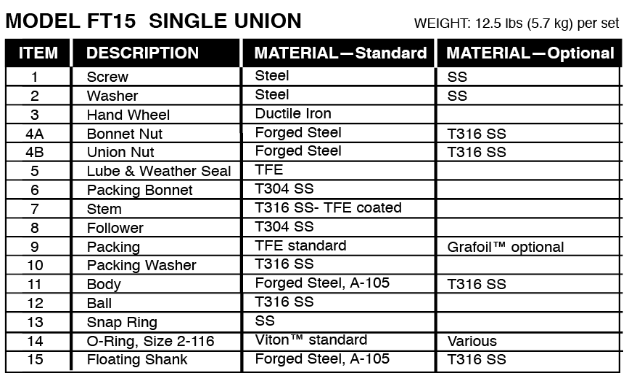

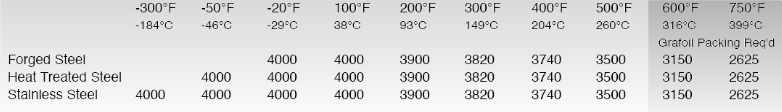

PRESSURE / TEMPERATURE RANGES

Maximum working pressure, PSI

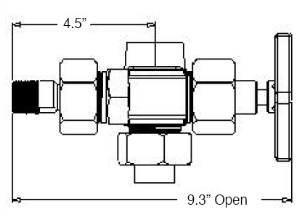

MODEL FT25-DOUBLE UNION

Wetted parts conform to NACE MR-01-75

WEIGHT: 15.25lbs (6.9 kg) per set

TO TIGHTEN PACKING:

When tightening packing, stem travels with bonnet towards seat. In closed posltlon, seating contact prevents further downward movement of packlng bonnet.

Valve must be at least partially open before packing nut can be tightened.