ANNOUNCEMENT- A better Gage Valve

for use with Liquid

Level Sight Glass Gages

Inferno Mfg. Corp

.

Shreveport, LA

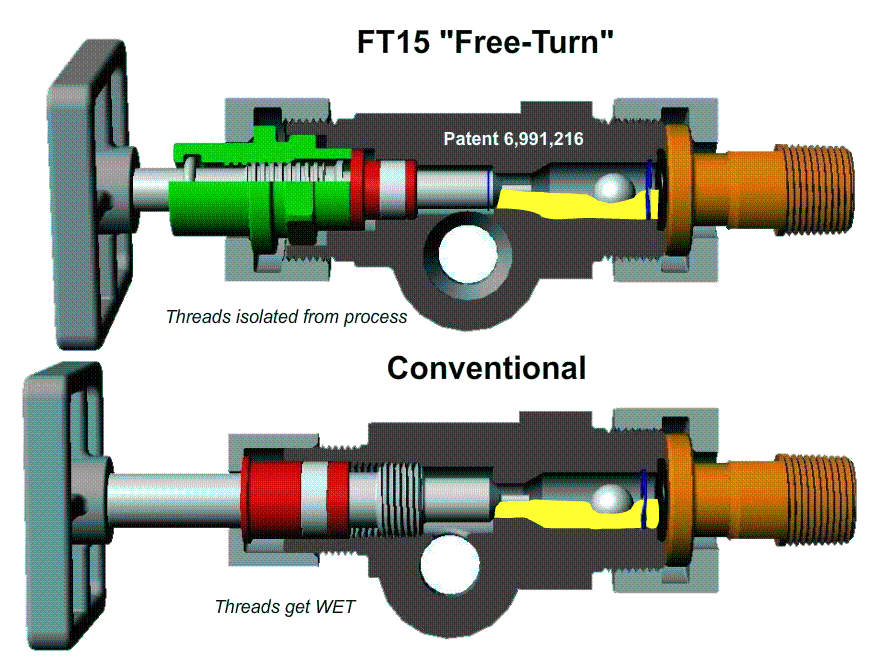

Inferno FT15 “Free-Turn” Automatic

Ball-Check Gage Valves: Unique packing design stops process from

reaching threaded area of valve.

Demo

available @ https://www.infernomfg.com/Fill.gif

https://www.infernomfg.com/Fill.gif

Compare

us to the competition !! Conventional models:

Penberthy 330J, Quest-Tec 1S, Jerguson 146, Mallard 3500, even our own Inferno 15A …

will seize up in brine service

Save

$$$

Why pay for a conventional valve such as a 330J that is likely to lock-up?

Why pay the extra expense of double blocking your sight glases with ball valves because you know the conventional

gage valves will fail? Get your full money’s worth… Specify the FT15

“Free-Turn” on your next project.

Switch to a gage valve that actually works !!!

Keep

your glasses clean

The key to gage glass

maintenance is the ability to isolate the gage column for blowdown

and swabbing. For effective cleaning, the gage glass must be blocked from the

vessel and de-pressurized before it can be swabbed. This is not possible if the

valve fails to operate- unless redundant block valves are installed between the

gage valve and the vessel.

Production supervisors

Gage valves must be in working order to knock the ball checks out of the

way after gage glass has been drained and blown down. When a conventional valve

seizes, the stem cannot be turned against the ball check to dislodge it from

its seat… The liquid level fails to re-establish in the glass. With

conventional gage valves the ball checks can become a nuisance. With the FT15,

ball check management is easy.

Safety

Using a pipe wrench on a gage valve to un-lock a frozen stem while the gage

glass is under pressure is bad practice. Remove the incentive for trouble:

design and build your equipment with the FT15 “Free-Turn” valves,

designed to perform in an environment where corrosion happens. All parts

conform to NACE…. AND corrosion in the steel body will not cause the valve

stem to seize.

H2S (Sour) Service

Combined with water H2S becomes highly corrosive, attacking the iron in the

steel valve body to form iron pyrite, a black, grainy substance, very sharp and

gritty. The pyrite quickly clogs the internal threads of a conventional gage

valve— acting even faster than brine to cause your valves to seize up.

Protect your valuable investments. Order your well head production separators

with Inferno gage glasses and FT15 gage valves.

Ordering sight glass gages and valves “per NACE” is not good

enough. Built “per NACE” – MR-01-75 conformance – just means the materials of construction are

resistant to stress corrosion cracking. Forged steel, for example, conforms to

NACE but it does corrode and it is the rust and/or the pyrite that kills

the workings of the valve.

Attention Haynesville shale gas producers

Haynesville formation gas frequently contains H2S. Specify FT15

“Free-Turn” gage valves on your new production separators.

Attention Midstream facilities engineering & construction managers

Amine plants… H2S removal

Compressor scrubbers, Dehydrators etc…

Handling high volumes of gas increases the chances for contact with H2S. Specifity FT15 “Free-Turn” gage valves on your

new vessels.

Who’s using FT15 “Free-Turn” valves?

J-W Operating

Camterra Operating

Southwestern Energy Company

Regency Gas

Enbridge Gas Pipeline

Petrohawk

Centerpoint Energy

Tetra Production Testing

XTO

Trend Gathering & Treating

Prism Gas

CAM Compression

Targa Resources

Ceritas Energy

El Paso Field Services

Lion Oil

Gulf South Pipeline

Calumet Lubricants

Designed in Shreveport. Built in Shreveport. Stocked

and Serviced in Shreveport

.

Ask your supply store or vessel fabricator for the FT15. Or, call us direct for

trouble shooting, recommendations, service problems etc. We’ll come to

you.

The key to better gage glass performance is in the

valve.

Brochure attached.

Thank you.

Allen B. Organick

President

allenorganick@infernomfg.com