MODEL FT15 GAUGE VALVES

APPLICATION

Pressure Rating: 4000PSI & -20°F to 100°F 3820PSI & 300°F 3500PSI & 500°F

TO TIGHTEN PACKING:

When tightening packing, stem travels with bonnet towards seat. In closed position, seating contact prevents further downward movement of packing bonnet.

Valve must be at least partially open before packing nut can be turned. If stem is closed packing cannot be tightened.

MODEL FT15 PARTS LIST

WEIGHT: 12.5lbs (5.7 kg) per set

| ITEM | DESCRIPTION | MATERIAL-Standard | MATERIAL-Optional |

|---|---|---|---|

| 1 | Screw | Steel | SS |

| 2 | Washer | Steel | SS |

| 3 | Hand Wheel | Ductile Iron | |

| 4 | Nut | Forged Steel, A-105 | T316 SS |

| 5 | Lube & Weather Seal | TFE | |

| 6 | Packinng Bonnet | T304 SS | |

| 7 | Stem | T316 SS | |

| 8 | Follower | T304 SS | |

| 9 | Packing | TFE standard | Grafoil™ optional |

| 10 | Packing Washer | T304 SS | |

| 11 | Body | Forged Steel, A-105 | T316SS |

| 12 | Ball | T304 SS | T316 SS |

| 13 | Snap Ring | SS | |

| 14 | O-Ring | Viton™ standard | Various |

| 15 | Floating Shank | Forged Steel, A-105 | T316 SS |

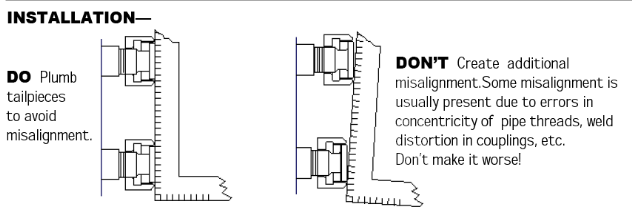

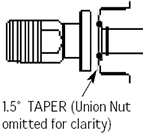

DO Make up unions tight. Use at least an 18″ wrench. Union is designed to crush solid metal along a high ridge, creating a “line” seal between the taper and the flat surfaces.

Union will seal pressure without need for O-ring if alignment is good enough and if the installation torque has been efficiently transmitted into tightening the joint

However, if there is significant misalignment in the piping arrangement then some of the “umpf” experienced during make-up has been diverted into deflecting the piping. This causes resistance to further turning of the nut and may leave insufficient tightness in the metal to metal seat of the union for sealing. In this case the O-ring will finish the job. The joint needs to be tight enough to close the extrusion gap for O-ring to maintain its seal. Make sure that O-ring does not disengage from the counterbore area during installation. If the rubber has become compressed and stiff it may tend to fall out of the valve body during installation. If this happens use a dab of grease or adhesive to keep the O-ring in place. If the O-ring has become stiff or shrunken due to age or cold it may sag out of position and become pinched in the joint. The union joint will not seal if this happens. The O-ring must be replaced or removed.

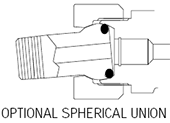

More severe MISALIGNMENT can lead to leaks at the union or broken pipe nipples or broken tailpieces. If you are experiencing these difficulties ask for Inferno SPHERICAL UNIONS available built into the valve itself as shown at right – or as a separate male x male union fitting between the gage and the valve when using Close Hook-Up (Side Connected) gauges.

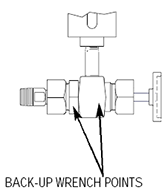

DO Make up unions using a BACKUP WRENCH on the valve body.

Failure to use back- up wrench causes excessive stress on the connecting nipple and can lead to breakage of nipple or harmful twisting to sight glass.

OPERATION BALLCHECKS…

Open valves full open during operation to assure safety action of ball check in case of – glass or gasket failure. Stem must be open more than 1- 1/2 turns before ball is allowed to back seat. Extension on end of stem will deny ball a seating position until valve is opened sufficiently. At this point the extension of the stem retreats enough to allow

ball to check closed in event of sudden loss of pressure in the sight glass.

Ball checks are designed to limit flow from vessel in case of accidental glass or gasket failure. They can be of great help in limiting the blow- out effect of pressure acting on a shattered glass. But they are not intended to provide a perfect seal. Dirt, trash and corrosion in the ball check cavity and back seat area will limit the tightness of the emergency shutâ€off. In such cases there may be some degree of leakage past the ball checks.

Ball check will not activate in case of seepage caused by a leaky gasket. Ball check may not activate at all if cavity is packed with corrosion. Ball check requires pressure in the vessel to activate. About 7″ head of water is sufficient pressure to check the ball in water service with a full flow leak. More pressure is required to check with a choked off leak. Performance in other fluids will vary. Ball check may not activate in extremely viscous fluids.

If in doubt as to whether ball checks are present in an existing installation or whether or not they are working properly you can test as follows: Close off the upper gage valve. Leave the lower valve open. Open a drain valve rapidly and listen for the ball to make an audible “click”. Now repeat process reversing the upper and lower valve position.

Restore fluid level in sight glass by closing drain and then moving both valves into the cracked open position. Cracking the valves open will cause the stem extension to unseat the ball and allow it to drop back into its normal resting place.

If sight glass fails and balls are activated then manually close both valves. Beaware that a small amount of fluid will escape as the balls are dislodged and before stem has a chance to fully close. Take necessary precaution.

BLOW-DOWN… DON’T blow down sight glass with valves open. High velocity flow will cut seat and lead to failure of valve to close without leakage. This problem is especially common in steam and hot water applications. However if it is not convenient to blow-down the hot water sight glass with valves in the closed position then DO install a second valve (ball or gate) to insure that a tight shut-off can be made for maintenance purposes during normal plant operation. A double block system may be required if you experience cutting in the seat area.

Shut off upper and lower valves first, then blow down sight glass through the lower valve’s drain connection, or through an additional outlet at the bottom of the sight glass. Restore fluid level in sight glass by closing vent and drain and then cracking open the upper and lower valves. Cracking the valves open prevents nuisance ball checking. After level has been reestablished open the valves full open. In the full open position the ball is able to check autmatically in case of glass failure. In cracked position it will not check.

SHUTDOWNS… It is usually best to leave valves in normal full open position as the system is de-pressurized. This prevents excessive thermal stress on the sight glass and valves and prevents trapping high pressure fluid. During START-UP pressure and temperature are allowed to equalize slowly in the sight glass.

SPARE PARTS-

O-ring, Viton™, Size 2-116 (90 durometer)

O-ring, Viton™, Size 2-116 (90 durometer)

3/4″ NPT Tailpiece, Steel

3/4″ NPT Tailpiece, Steel

1/2″ NPT Tailpiece, Steel

1/2″ NPT Tailpiece, Steel

Union Nut, Steel

Union Nut, Steel

Stem Packing, Teflon™ standard, to 500F

Stem Packing, Teflon™ standard, to 500F

OPTIONAL MATERIALS

O-Ring, Aflas™, for hot water & steam, amine service

O-Ring, Parofluor Ultra, for hot water & dry steam to 525°F

StemPacking, Grafoil™, over 500°F

OPTIONAL CONFIGURATION

Spherical Vessel Connections, 3/4″ and 1/2″ M-NPT

COMMENTS AND SUGGESTIONS WELCOME

INFERNOMFG.CORP. SHREVEPORT,LOUISIANA www.infernomfg.com

TEL: 318-221-8454 FAX: 318-222-4106 email: [email protected]