End Connected Vs Close Hook-Up Level Gages

End Connected

-Large stock of inventory (with 1/2" F-NPT)

-Less expensive than Close Hook-Up

Close Hook-Up

-Custom made to fit on vessel centers

-Offers longest possible view length

Why Is My Level Gage Leaking?

-Expansion forces during freezing cause high internal pressures, which can damage the seals and the glass

-If the process includes water, the level gage must be heat traced and insulated to prevent freezing

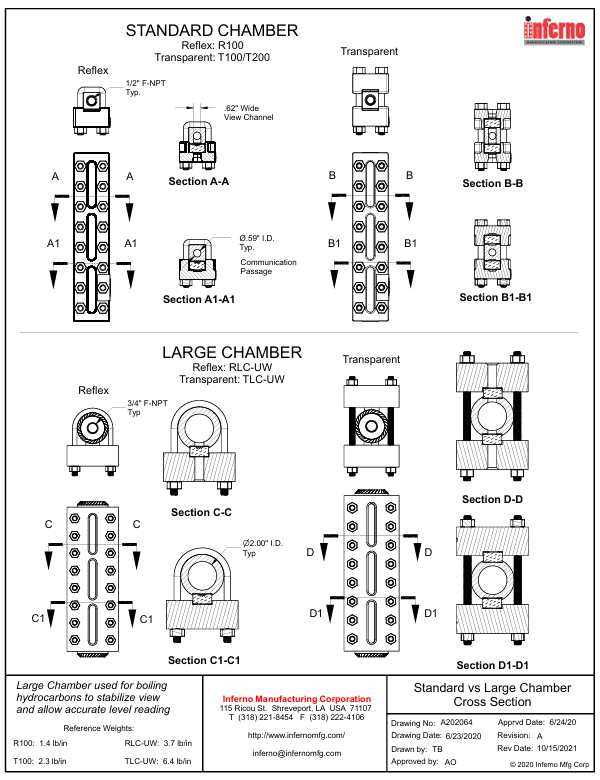

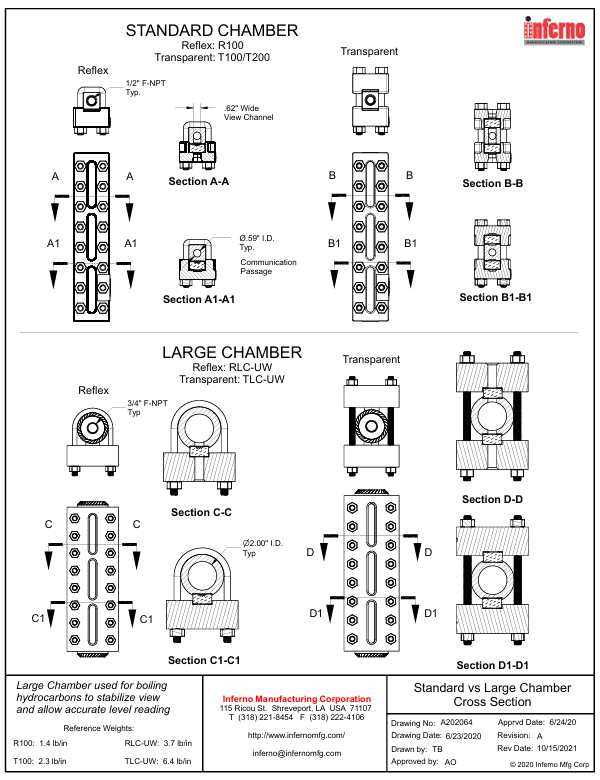

Standard Chamber vs Large Chamber

Standard Chamber

-Used for stable liquids where the level doesnt jump or surge

-Inventory item

Large-Volume / Large-Chamber

-Used for boiling hydrocarbons to stabilize view and allow accurate level reading

Steam Non Boiler

-For applications per ASME B&PVC Section VIII (Pressure Vessels) where the vessel nameplate has an ASME "U" Stamp

-Reflex style, 250 wsp

-Transparent style, 450 wsp with mica shields

Steam boiler

-For applications per ASME B&PVC Section I (Power Boilers) where the vessel nameplate has an ASME "S" Stamp

-Reflex style, 250 wsp

-Gage valves with quick closing threads available

Flat Glass Gages

-Heavy-duty gage glass in a solid metal body

-Higher pressures and much more resistant to breakage as compared to tubular glass

-Reflex and Transparent style with 1/2" NPT end connections in stock (up to 5 sections)

Tubular Glass Gages...

-Lower pressures

-Less expensive

-Large inventory of 5/8" O.D. plain/clear and red line

-Available in 2 options...

Bare Glass Tube protected by expanded metal "Hail Guard" or guard rods

Armored Tubular Sight Glass, rated to 315 or 500 psi

Model TE Armored Tubular vs Bare Glass

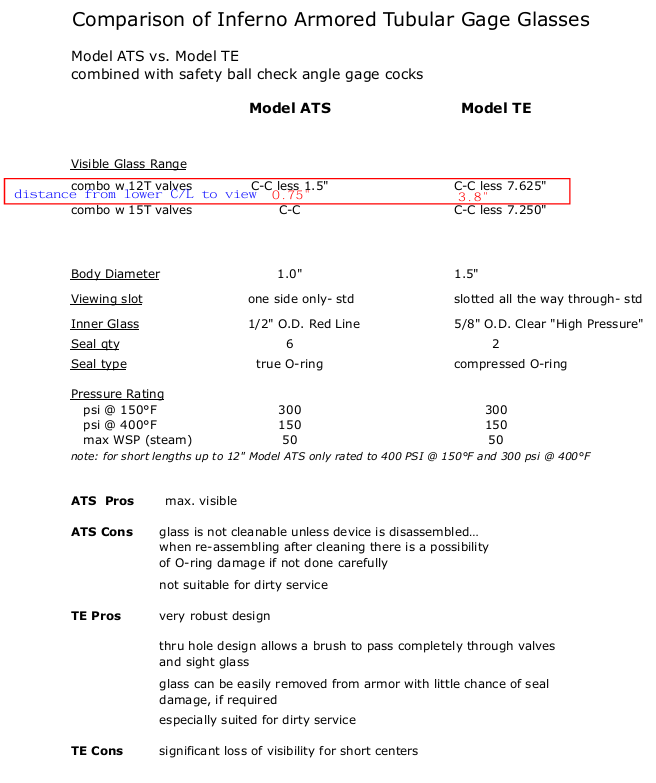

Model TE Armored Tubular vs Model ATS

Transparent: T100 or T200

T100 series carries higher pressure ratings as compared to T200

Free Turn vs Conventional

Single Union vs Double Union (For Flat Glass Style Level Gages)

Single-Union Gage Valves

•Union vessel connection (with +/- 1/4" float) x non union gage connection

•Allows use of longest end connected level gage

Double-Union Gage Valves

•Union vessel connection (with +/- 1/4" float) x union gage connection

•When used with end connected level gage, the second union at the gage allows 360 degree rotation

•Union gage connection allows for removal of gage for cleaning or maintenance while valves are installed and vessel under pressure

Flat Floating Union vs Spherical Union (For Flat Glass Style Level Gages)

Flat Floating Union

• May be used with end connected or "Close Hook-up" style level gages

Spherical Union

• Offered for "Close Hook-up" style level gages

• Recommended for angular misalignment which can be caused by non jigset construction, or for horizontal vessels with field constructed piping

• Recommended for long and heavy level gages and/or vibration service. Reason: Increased bending strength compared to flat floating union

• Not recommended for end connected level gages (ball and socket joint does not allow for variation in vessel c-c)

Low Emission Gage Valve Stem Packing

-Free Turn series (FT15, FT25, and FT-Tub) is available with fugitive emission API 622 valve stem packing (Flexible graphite with NiCr wire)

-Certified to ISO 15848-1

Straight vs Offset Pattern

Straight Pattern

• Less expensive

• Glass disassembly is required for cleaning

• Model 12T and Conbraco 20-250

Offset Pattern

• Allows "straight through" access for cleaning brush, no glass disassembly is required

• "Free Turn" series, 15A, and 15T

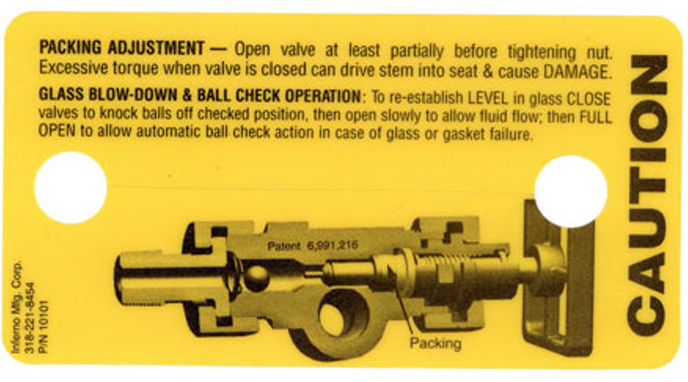

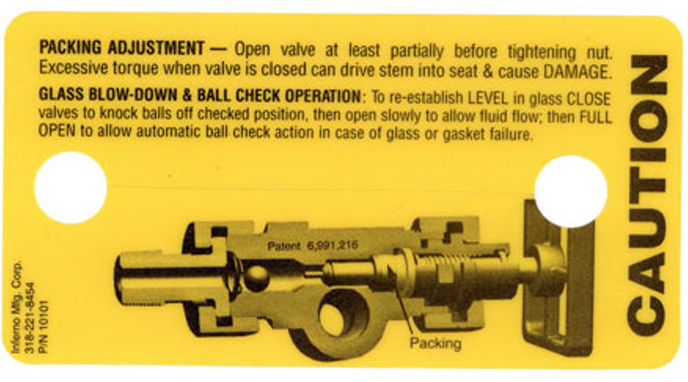

Why Are My Gage Valves Leaking?

Most FT15 or FT25 leakage problems are solved by tightening the packing nut while the valve is open; not closed

Stock items usually ship 1–2 business days ARO

Custom jobs typically 2–3 weeks ARO

Need it faster?

Just call or email

318-221-8454

[email protected]• Reflex level gages with 1/2" end connections, sizes 13-59 in stock (CS)

• Transparent gauges with 1/2" end connections, sizes 13-49 in stock (CS)

• Bare tubular glass & expanded metal gaurd protectors in stock up to to 48″ long

• If its not on this list then standard lead time is generally about 2-3 weeks